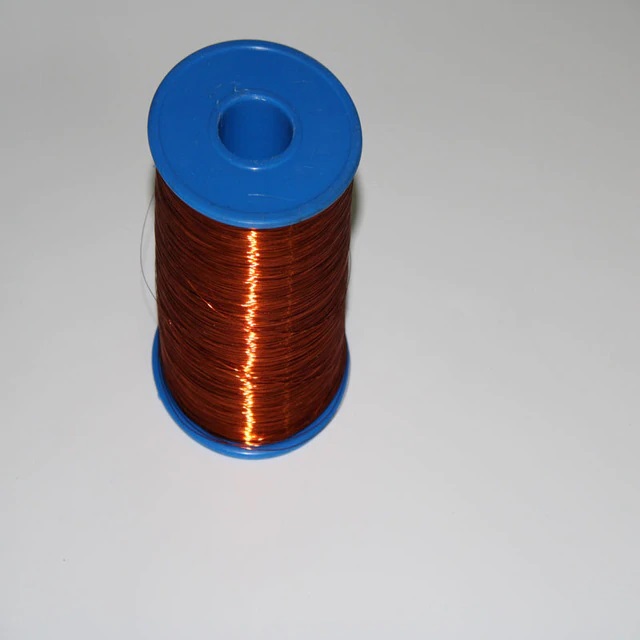

Magnet wire is a copper wire coated with a thin layer of insulation used for the applications to tight coils of insulated wire in the construction of inductors, motors, electromagnets, transformers, and hard disk head actuators.

The electrically refined copper wire itself is more often tempering. Transformers and motors are acted as an aluminum magnet. By the polymer film materials of enamel is used for insulation. The unalloyed pure metals are called as copper are most suitable to magnet wire applications. Magnet wire’s considered the copper as the primary choice for physical, mechanical and chemical properties.

What are the properties of copper wire?

Copper is extremely acted as a conductor to transform the electrical energy. Copper winding wire is classified by the diameter mentioned in the millimeters, insulation class of wire and their temperature class. There are 3 grades are classified to use for the particular application. High grades in the copper wire have thicker insulation that will affect the higher breakdown voltages.

- Good conductor for electricity

- Good conductivity in thermal

- Corrosion resistance

Properties included in the copper winding wire as it’s easy to alloy, easily joined, Non-magnetic, recyclable item to attractive, antimicrobial in tough ductile, they are catalytic in nature.

What are the benefits of using copper wire in daily life?

Copper winding wire is used in electric motors to convert the electrical energy to mechanical energy. In the transformer device, the magnet wire helps to absorb the electrical energy from one circuit to transfer it to coils on another side.

Generators using copper wire to operate the higher temperature and increase the higher electrical conductivities. Deoxidized copper will conduct the electricity through the magnetic and bars. Oxygen-free copper will act in the electrical conductivities.

Copper conducts the electrical flows easily by the small electrical resistance without loss of energy. Copper winding wire cables are used in houses and underground electricity connections. Size of the copper rather than the weight is important for using the coils.

Without melting the coil or strip, a thick copper will carry the high current. It is easy to wound on a coil and produce the magnetic field without wasting the electrical energy. Copper conducts the heat by reaching the temperature quickly in the retained state.

Copper is suitable in which applications?

Copper atoms are closely packed together in the copper. The characteristic of a copper atom is to be lost one electron and become a positive ion, webbing of positive ions with free moving electrons.

- Copper is applicable on the electricity applications, electrons have a negative charge and they are attracted to the positive end of the electrical components.

- Copper allows many applications to heat quicker. The quick heat transformer passes the heat very quickly to the copper pipes, heat sinks, and copper plate.

Comparing the copper with the non-metal heat conductor, copper will pass the vibrant to the vibrant particles to their nearest conductors. The free electrons in the copper will carry the energy along in their range, but the metals conduct the electrical energy slowly.